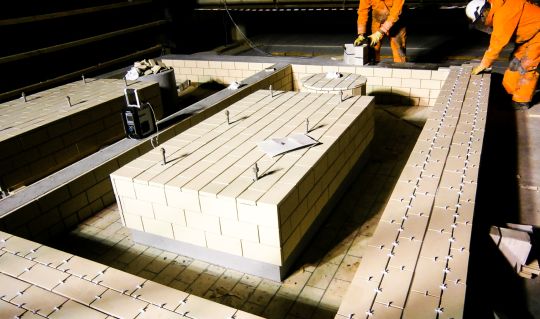

Our expert team provide design, supply and construction of new chemical refractory linings and membranes and have vast experience in replacing existing systems that are either at failure or end of life cycle. We also supply and install Metz specialty acid bricks and tiles.

Acid bricks and tiles differ from typical commercial bricks and tiles in several ways with the most significant physical difference are in the low absorption rates and variety of physical shapes available.

Low absorption rates are essential to ensure dangerous chemicals do not penetrate the ceramic lining systems. Acid bricks are available in a multitude of special shapes to ensure complex and sometimes very large shapes can be lined in a manner maximising chemical and abrasion resistance.

Acid Tiles

Metz Acid Tiles are acid resistant, heavy duty ceramic tiles manufactured to provide chemical and wear resistant floors and linings for chemical, food and beverage plants.

Acid tiles are commonly much thicker than conventional tiles. Typical acid tiles are 20–25 mm thick, whereas most commercial floor tiles are 5–8 mm thick. This additional thickness contributes to high strength and a highly chemical resistant ceramic lining capability.

Normally extruded acid resistant tiles are used, although dry pressed products are available. Abrasive surface tiles are available for areas with a high chance of slipping. Special cove pieces are available as standard. Other special shapes are possible dependent upon project size.

Acid Bricks

Metz Acid Bricks are a red shale, extremely high-density acid brick available in a huge range of special sizes and shapes. Both standard bricks and tailored linings are available.

Metz also manufacture a range of corrosion resistant fixing materials to complement these acid resistant ceramics which means a complete acid proof lining system from a single source is possible for our clients.

If you are interested in learning more about our Acid Refractory Bricks and Ceramics services, please contact our friendly team.